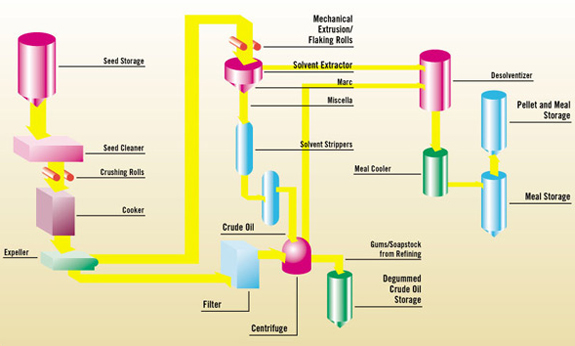

Though it may appear like an obvious process, the solvent extraction process is an abstract process in the minds of the layman. Consumers are mainly concerned with the final product but they do very little to understand the process. This process involves extraction of oil from materials that produce oil using a solvent. The most commonly used solvent is hexane, a petroleum byproduct. This process is made possible with the help of solvent extraction plants. The particular oil in question is extracted using chemicals through a series of processes.

It is important to understand each of these processes because any mistake that you make could jeopardize the final product that you intend to produce. The basic raw material for oil extraction is the cake which is derived from the press section of the solvent extraction plant. This cake is then dissolved using an organic solvent after which this solvent is evaporated. In order to cut down on the cost of purchasing the organic solvent, it is usually recycled. If you have future plans of establishing a solvent extraction plant, you need to ensure that you have done your research well and that the staff that you recruit is professional and vast experienced in this area so that you can realize its full benefits.